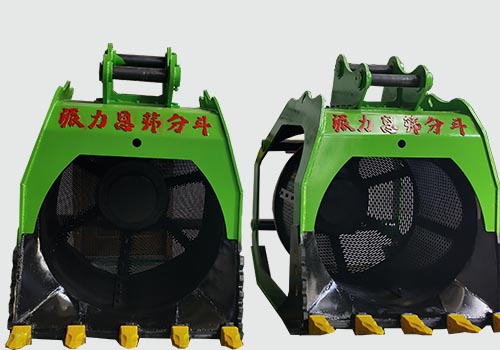

產品詳(xiang)情(qing)

鑄件(jian)澆(jiao)冒口分離器工(gong)作原理(li):工(gong)藝(yi)流程是:油泵站(zhan)接380伏電源(yuan),油泵站(zhan)和分離器通過2根(gen)高壓(ya)(ya)油管(一(yi)進一(yi)出(chu))連(lian)接,分(fen)(fen)離器由平衡葫蘆(lu)吊懸掛方便操作。以下是工作原理(li)。鑄件澆冒(mao)口分(fen)(fen)離器通過液壓(ya)(ya)泵站產生18-70MPa液(ye)壓動力(li)。開機時,按下鑄件分離器手把(ba)開關,油泵站由低(di)壓泵送油,當壓力(li)達到18MPa,高(gao)低(di)壓切(qie)換閥切(qie)斷低(di)壓泵(beng),這時,由高(gao)壓柱(zhu)塞(sai)泵(beng)工作送油,高(gao)壓柱(zhu)塞(sai)泵(beng)產生大70Mpa工作壓(ya)(ya)力(高(gao)低壓(ya)(ya)切換(huan)原理就是(shi)低壓(ya)(ya)泵快速送大(da)量(liang)(liang)的油(you),而高(gao)壓(ya)(ya)柱塞泵是(shi)少量(liang)(liang)油(you)產生(sheng)高(gao)壓(ya)(ya),大(da)程度防止大(da)量(liang)(liang)油(you)進出,防止油(you)泵站升溫),油(you)管(guan)內高(gao)壓(ya)(ya)油(you)推(tui)動(dong)(dong)(dong)(dong)分離(li)(li)(li)器(qi)(qi)油(you)缸內活(huo)塞,活(huo)塞推(tui)動(dong)(dong)(dong)(dong)前端尖(jian)鐵(tie)(tie),尖(jian)鐵(tie)(tie)向兩邊推(tui)動(dong)(dong)(dong)(dong)楔鐵(tie)(tie),以上油(you)壓(ya)(ya)一系列動(dong)(dong)(dong)(dong)作產生(sheng)大(da)噸分離(li)(li)(li)張(zhang)力,將(jiang)鑄件(jian)澆冒口分離(li)(li)(li)器(qi)(qi)從母體分離(li)(li)(li)下來(lai)。